Reasons Businesses are Choosing Heat Pumps

The International Energy Agency (IEA) estimates that heating accounts for approximately 50% of energy use and up to 10% of global CO2 emissions. Industrial heat pump solutions are efficient and eco-friendly and are becoming an increasingly important sustainable solution in the decarbonisation of industry.

- The central technology: all experts agree that heat pumps are the central technology in the global transition to secure and sustainable heating. They have the potential to reduce global carbon dioxide emissions by at least 500 million tonnes by 2030.

- Cost-effective: because most of the heat is transferred (from the air, ground, or water) rather than generated, heat pumps are far more efficient than conventional heating technologies (such as gas or oil-fired boilers) and are more cost-effective to run. They provide several times more energy output than energy input. This high energy efficiency translates into significant energy savings, reducing both greenhouse gas emissions and energy costs.

- Low carbon emissions: heat pumps emit lower carbon emissions, especially if supplied with electricity from zero-emission sources such as solar, wind, and nuclear power. Then they can be emissions free.

- Versatility - heating, cooling and process heat: industrial heat pumps can replace conventional heating, ventilation, and air conditioning (HVAC) systems, including gas and oil-fired furnaces and boilers, low-efficiency air conditioners, electric resistance furnaces, and electric resistance unit heaters

- Process heat: heat pumps can also be used to capture and store heat from industrial processes (such as manufacturing and chemical production) and then transfer it to a different process (such as heating a building or providing hot water). This reduces the amount of energy that would otherwise be needed to generate the same amount of heat. (Heat pumps can also be used to preheat water before it enters a boiler, reducing the amount of fuel that needs to be burned to generate steam).

- Cross-sector potential: the potential to provide process heat is immense. Industrial heat pumps are used for processes below 100 °C, notably in the paper, food and chemical industries. But output temperatures of up to 150 °C+ can be achieved if waste heat of about 100 °C is available as input.

- Price security: due to their high energy efficiency, heat pumps can reduce energy consumption and lower energy bills, resulting in cost savings over time. Additionally, as renewable energy sources used by heat pumps are not subject to price fluctuations, heat pumps provide a stable and predictable source of heating, reducing the risks associated with fluctuating fuel prices.

- Government Incentives: many governments are actively promoting the adoption of heat pumps as part of their decarbonisation strategies. They offer various incentives, such as tax credits, rebates, and energy grants which can significantly offset initial Capex outlay.

- Technology, expertise and rising demand: the rate of installation is increasing rapidly. In 2021, global sales increased by almost 15%, double the average of the last decade. Growth in the EU was around 35% and is expected to accelerate further in light of the energy crisis. The technology is quickly evolving and becoming more powerful. In addition, engineering expertise, and know-how in this specialised area are growing.

Impact of Heat pumps

If governments meet all their climate‐related commitments (in full and on time), heat pumps will be the primary means of decarbonising space and water heating.

- The demand for natural gas, heating oil, and coal will fall so significantly that, in aggregate, heat pumps could account for nearly half of the global reduction in fossil fuel use for heating in buildings by 2030, with the remainder coming from other efficiency measures.

- Such rapid deployment will ultimately increase the world's need for electricity. This is why heat pump deployment alongside energy efficiency and demand response strategies will be vital to reducing the pressure on existing power and grid systems.

When Heat Pumps Make Business Sense

It is evident that businesses need to use heat pumps as one of their solutions to decarbonise space and water heating. Here are some of the best circumstances for installing heat pumps:

- Green power supply: a heat pump will significantly reduce carbon emissions if it can be fueled by green electricity (either generated directly onsite or through a power purchase agreement).

- When waste heat is available: if waste heat can be used to ‘prime’ the heat pump, this will maximise its efficiency, reducing its electricity consumption, operating costs, and carbon emissions.

- Carbon pricing: heat pump technology reduces scope 1 emissions and the associated carbon costs with those emissions. The long-term reduction of both contributes to the capex payback for the heat pump.

- High energy prices: the energy used by a gas or oil-fired boiler will be replaced with a heat pump. Heat pumps are a smart business decision if your prices are high or variable.

- Low-temperature heat loads: the lower the temperature (or heat load) required in the process, the better. The lower the discharge pressure required from the heat pump this results in higher efficiency and lower operating costs.

How do Heat Pumps Work

“The installation of a heat pump project at our main facilities transformed site efficiency. Our original refrigeration design never quite recovered heat as intended and used more energy. The heat pump project with CoolPlanet delivers the right results - 31% energy savings, 100 tonnes carbon savings per year, and 20% additional refrigeration capacity” - Neil Bradshaw, Engineering Manager, MyFresh.

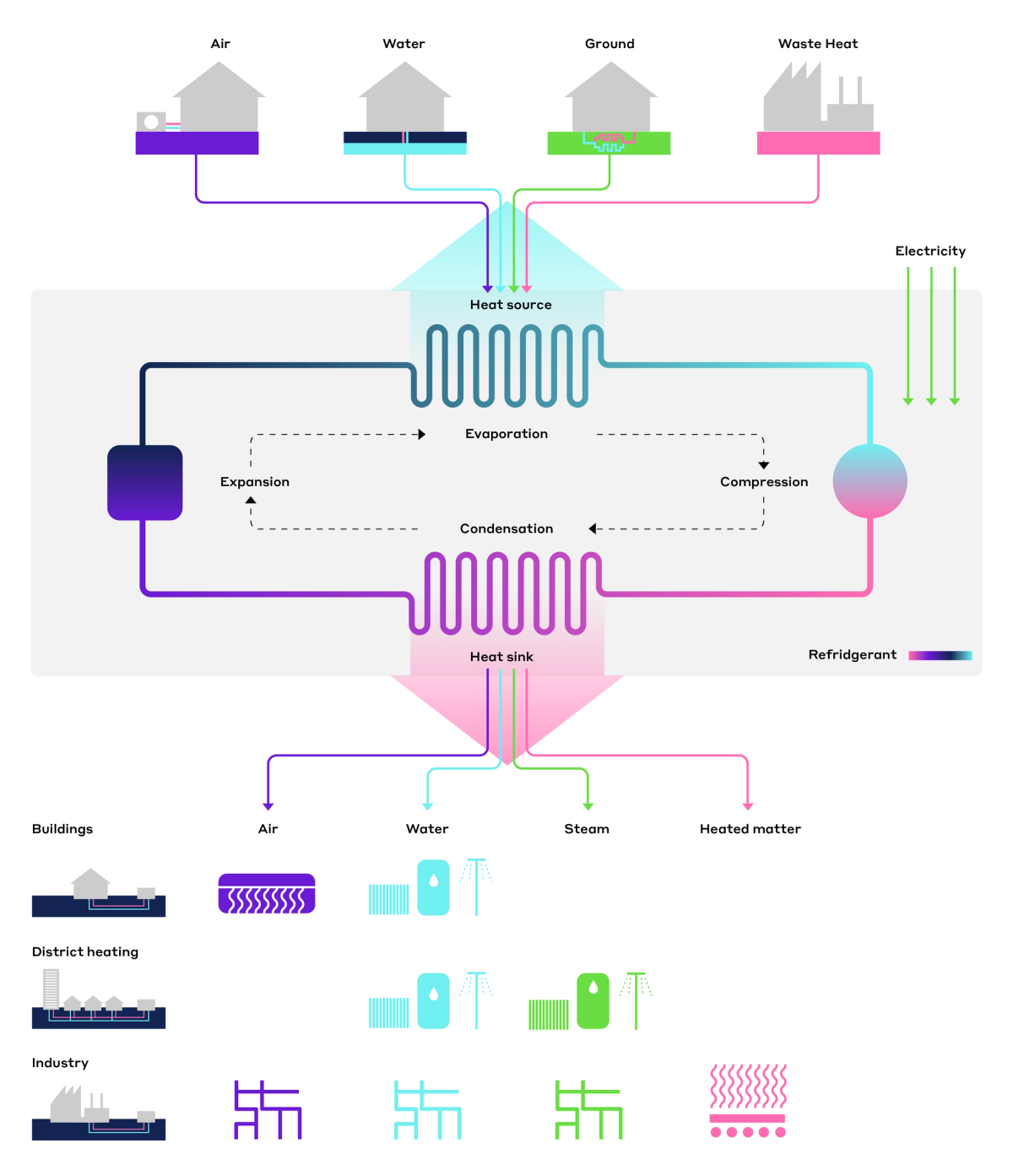

In industrial settings, heat pumps are used to deliver hot air, water, or steam, or directly heat materials. Large‐scale heat pumps in commercial or industrial applications (or in district heating networks) require higher input temperatures, which can be sourced from the waste heat of industrial processes, data centres or from wastewater.

The beauty of heat pumps as a decarbonisation method and the reason for their exceptional energy efficiency is that they combine heating and cooling into one device without the use of fuel. They do not produce new heat; instead, they move heat from an area of low temperature to an area of high temperature. It extracts heat from a source, such as the air, geothermal energy stored underground, nearby water, or waste heat from a plant or an industrial process. It then amplifies and transfers the heat to where it is needed.

Typically, an industrial heat pump will take heat from a source around 25-35°C and can output temperatures as high as 165°C. The efficiency of a heat pump declines with greater temperature increases.

An industrial heat pump uses technology similar to that found in a refrigerator (or an air conditioner) but operates at higher pressures. The heat pump itself consists of a compressor, which moves a refrigerant through a refrigeration cycle, and a heat exchanger, which extracts heat from the source. The heat is then passed on to a heat sink through another heat exchanger.

Performance of Heat Pumps

A heat pump’s efficiency is expressed as a coefficient of performance (COP), where a COP of 1 indicates a 100% conversion of electricity into heat. Heat pumps that deliver a temperature increase of 40-60°C often have a COP of three to four, meaning they are three to four times more efficient than a gas boiler.

A heat pump configured to deliver an output temperature of 165°C corresponding to a heat increase of about 130°C, has a COP of 1.5

Navigating the complexities of industrial heat pump technology

"With the help of CoolPlanet, we introduced a high-efficiency heat pump that uses waste heat from other processes to generate hot water for washdown and handwashing. We reduced carbon emissions by 80% and overall energy consumption by over 30%" - Trevor Lockhart CEO, Fane Valley Foods, UK

Introducing heat pump technology in industrial processes requires careful planning, design, and installation. Industrial heat pumps are often designed for specific processes and temperature configurations. Industrial facilities typically have warm wastewater or heated air flows that can serve as heat sources for generating higher temperatures.

However, the refrigerants used in industry must provide higher temperatures and are used in larger quantities, increasing environmental and fire hazards. Industrial heat pumps also operate at higher pressures, requiring thicker piping, and compressors must withstand higher temperatures.

Each facility has unique requirements, even for similar processes in the same industry. Moreover, the costs and feasibility of installing heat pumps for new processes versus retrofitting existing ones can differ significantly, as the installation process can be complex. Expert design and configuration are crucial to ensure the successful integration of heat pump technology in industrial settings.

Heat Pump Potential by Sector

The potential for industrial heat pumps varies by sector. For example

- In the food industry 40% process heat demand can be met mainly at temperatures up to 150 °C (there is limited availability of high‐temperature waste heat). About two thirds of the heat demand below this threshold could be met by heat pumps based on current waste heat availability. The potential could be even higher if heat sources from nearby facilities could be tapped into or if processes could be modified to run at lower temperatures.

- In the chemical industry, where most processes need high temperatures, heat pumps cover about a quarter of the process heat demand. Low temperature processes, however, gain from the large volumes of waste heat produced by other processes at the same site.

Of the combined heating needs of these industries, as much as 30% could be addressed by today’s heat pump technologies.

Summary

Overall, industrial heat pumps are an important part of the effort to decarbonise industry. Nearly 40% of all industrial heating demand up to 2030 will be at suitable temperatures.

By capturing and transferring heat from industrial processes, using renewable energy sources, and reducing emissions from refrigeration systems, industrial heat pumps are helping to reduce emissions and move the world towards a more sustainable future.

How CoolPlanet Can Assist you with Heat Pumps

Are you interested in advancing your organization's decarbonization journey? Or are you concerned about rising gas prices and the security of supply?

CoolPlanetOS can effectively map your refrigeration and heating needs, removing the guesswork from heat pump design.

CoolPlanet’s industrial heat pump can use renewable energy from the air, water or ground but also waste energy from buildings and processes to provide you with heating and cooling.

They are cheaper to run than gas boilers, produce less carbon emissions and can even provide you with free hot water. Schedule a call with CoolPlanet today.